Modifying Date Format of a BIP Parameter

Introduction

For all those from a EBS background we have been accustomed to submitting a XMLP Report from SRS Window which gives us the privilege of using a custom Data Type Value set in a Concurrent Program Parameter where-in we can enforce end users to pass Date values in a specific format. It may be dd/mm/yyyy, mm/dd/yyyy, dd-mm-yyyy, dd-mon-yyyy or any other date format. In standalone BI Publisher or even the same which is embedded within another application (say Oracle Fusion Application for example) the default format which is used for any date type parameter is a Java Date Type parameter(MM-dd-yyyy). Business users however are used to using specific date format applicable as per their regional settings and as such there is a genuine need of allowing other date type format too in the parameter. This article is intended to address the same specific issue, here we would try to demonstrate how we can change the default date format from a Java Format (MM-dd-yyyy) to any other format.

In this example we would demonstrate how to get the date value in say dd-MM-yyyy.

As a pre-requisite we would refer to one of the previous article which has a Date Type Parameter (pCalculationDate). We would try to change the Date format for the same parameter and try to understand the impact of the same. Also we would have a look at the results part too.

So now let’s try to check the below two screenshots and try to understand the same.

Date Format String

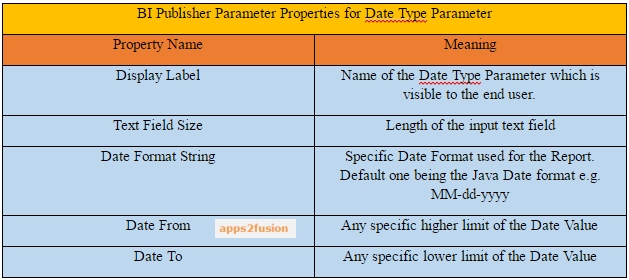

Each BI Publisher Parameters property section has the following properties for a Date Type Parameter:

Screenshot

We can see clearly that in the Date Format String has been changed to dd-MM-yyyy

And let-us see the results too:

Like we have used dd-MM-yyyy you may also use any other format like dd.MM.yyyy, dd/MM/yyyy

- SAP CROSS MODULAR ORGANISATIONAL HIERACRCHY

- Cross-Modular Integration(FI-MM)

- Introduction to Oracle E-Business Suite

|

Posted: 22 Jul 2016 08:02 AM PDT

The Various Modules provided by SAP ERP consists of an Organizational hierarchy to help its customers map its business structure in the system. FI is mapped in the system considering its internal and external reporting requirements. Likewise, Material Management has its own organizational elements, Sales Distribution has its own set of elements and so on. It helps creating diversity amongst modules and also by mapping these units to each other we can achieve integration at the same time. We can also by doing so have an 1:n mapping using one company code to map multiple MM Organizational elements therefore including physical locations for the business.

Let us see a combined organizational hierarchy for an organization as a whole with various modules and its mapping. A brief definition on these organizational units will help you understand the purpose and their position in the hierarchy

Material ManagementPurchasing Org: Purchasing Organization is an organizational unit under Company Code or plant, which is responsible for external procurement activities as per requirement. It can be specific to a Plant or Company Code. A purchasing organization can be further divided into purchasing groups.Purchasing Group: Purchasing Group is an organization unit, which is responsible for day-to-day procurement activities within an organization. Plant: Plant is an organizational unit within a Company where activities take place. A plant will produce goods and makes goods available for use by the company. Storage Location: Storage Location differentiates between different material stocks in a Plant. It is a place where stock is kept physically. Plant can be consisting of various storage locations. Controlling

Operating Concern: Operating Concernis the highest level in SAP Controlling Module if you want to implement SAP profitability analysis. (COPA).Your business will be divided into segments (i.e. by product, marketing and other segments)and each segment can be analyzed through this module. It creation is client independent.

Controlling Area: An organizational unit within a company used to represent a closed system for Cost Accounting Purposes. A controlling Area can be attached to single or multiple Company codes with different currencies but a single operating chart of Account. All internal allocations refer exclusively to objects in the same controlling area.

Sales and Distributions.

Sales Area: SD is organized according to Sales Organization, Distribution channel and Division. A combination of these three organizational unit forms a Sales Area.

Sales Organization: It is an organizational unit within Logistics that structure the company according to the sales requirements. A sales organization is responsible for sales and distribution of goods and services. It represents the selling unit as a legal entity. A sales organization can be divided in several distribution chains, which determine the responsibility for a distribution channel. Several divisions can be assigned to a sales organization. Each organization is assigned exactly one company code for which you enter all accounting details of the sales organization.

Distribution Channel: The distribution channel represents channel through which salable materials or services reach customers. For Example: Wholesale, retail an direct sales. A single distribution channel can be assigned to one or more sales organizations.

Divisions: Product groups i.e. divisions can be defined for a wide range of products.

Human Resources:

Personnel Area: A Personnel Area is a Personnel Administration specific unit and is a subunit of Company Code. The Personnel Area represent a subdivision of the company code. The Personnel Area can be used to perform system evaluation of data or to perform authorization checks. Personal Area is assigned to a Company code.

Personnel Sub Area: A Personnel Sub Area is an Organizational unit that represents a specific area of the company organized according to certain aspects of personnel, time-management and payroll. The following business subtasks belong to sub area.

To visualize an overall Organizational Structure of a Company the below diagram will help to understand an Overview and its hierarchy.

In the above diagram I would like to highlight some fundamental concepts considering its mapping relations and individuality. The below points will help you understand the ratio of mapping .1 to n or 1 to 1 relationship that exist between the organizational units, hence making your configuration simple. These concepts need to be very clear in order to face the client and construct a blue print for their organization in the Implementation stage.

|

|

Posted: 22 Jul 2016 07:20 AM PDT

SAP As an ERP facilitates its customers to cover all business processes.Simple processes and complex processes. Organizational Business transactions are available in SAP standard functionality, which can be customized and configured as per our industry and Company specifics. Higher the level of integration easier is the mapping of these economical business situations. SAP has Various Modules and they are integrated with each other as a system. Various SAP Functional Modules provided by SAP are:

|

|

Posted: 21 Jul 2016 03:54 PM PDT

Introduction to Oracle E-Business suite:

Oracle E-Business Suite (EBS) version R12 is an internet enabled product that can be managed from the single site. A company can operate a single data centre with single database, similar to the ERP products. This release was launched in Feburary 2007 and contains number of product lines which users can implement for their business. Oracle EBS includes the company's enterprise resource planning(ERP) product as well as supply chain management (SCM) and customer relationship management (CRM) applications.

The applications found in the Oracle EBS include:

Oracle Customer Relationship Management (CRM)

The Oracle CRM application provides the "front office" functions which help a business to increase customers and customer loyalty and satisfaction.The basic functionality includes marketing, order capture, contracts, field service, spares management and the call center functionality. The CRM application also includes internet focused products such as catalogs, content management, quote and order management.

Oracle Financials

The Financials applications include General Ledger, Cash Management, Payables, Receivables,Fixed Assets, Treasury, Property Management, Financial Analyzer and a self-service expenses function.

Oracle Human Resource Management System (HRMS)

The HRMS application helps companies manage the recruit-to-retire process. The application gives users a real-time view of all the HR activities, including recruiting, time management, training, compensation, benefits and payroll. The HRMS suite integrates fully with the other EBS applications and supplies the users with an analytics package that allows the extraction of HR data with ease.

Oracle Logistics

The logistics module allows users to plan, manage, and control the flow and storage of products and services within a business. It provides information to plan future demand and safety stock within the warehouse. The application can create detailed, constraint-based production schedules and material plans.

Oracle Supply Chain Management (SCM)

Supply chain applications powers a business's information-driven supply chains. Companies can predict market requirements, innovate in response to volatile market conditions, and align operations across global networks. Oracle offers industry-specific solutions that includes product development, demand management, sales and operations planning, transportation management, and supply management.

Oracle Order Management

Order management applications can streamline and automate a business’s entire sales order management process, from order promising and order capture to transportation and shipment. Order management also includes EDI, XML, telesales and web storefronts. Some of the business benefits that can be achieved include reduced fulfillment costs, reduced order fulfillment cycle time, increased order accuracy and greater on-time delivery.

Oracle Transportation Management

Transportation management (TMS) provides transportation planning and execution capabilities to shippers and third party logistics providers. It integrates and streamlines transportation planning, execution and freight payment. The TMS function delivers functionality for all modes of transportation, from full truckload to complex air, ocean, and rail shipments. The benefits of the TMS function include reduced transportation costs, improved customer service and greater asset utilization.

Oracle Warehouse Management System

Oracle’s Warehouse Management System allows the coordinated movement of goods and information throughout the extended distribution process. The module provides business processes that can deliver efficient utilization of employees, equipment, and space in the distribution process. Benefits include an acceleration of the flow of products through the supply chain while reducing lead times and releasing working capital, real time inventory management, cross-docking, pick-by-line, advanced ship notices (ASN), inbound planning and yard management.

Oracle’s ERP product is second only to SAP in sales and its best of breed solution can be found in thousands of companies across the world. The applications that are included in the E-Business Suite cover the wide range of business processes that are found in any company. The industry-specific solutions supplied by Oracle can easily reduce time and resources required to implement the solution and provide businesses with configured business processes that will improve overall effectiveness.

|

|

Posted: 26 Jul 2016 04:12 AM PDT

SAP ERP provides its customers with various modules to cater its business requirements. SAP Finance being one of the highly integrated modules runs through all the other modules. To Map the system with our business requirement firstly we need to understand the definition of the SAP FI organizational Structure and its overall usage and purpose. After understanding the same we can be in a position to decide which of the organizational hierarchy units do we need to use and not.

| |

|

Posted: 26 Jul 2016 03:59 AM PDT

CONTROLLING:

Controlling CO is an independent module in SAP ERP system. It has its own master data, data tables, configuration, processes, allocations, derivation, assessment, settlements, integration with other modules etc. Controlling provides you with information for management decision-making. It facilitates coordination, monitoring and optimization of all processes in an organization. This involves recording of both consumption of production factors and services as well as documenting actual events. The main task of controlling is planning. You can determine variances by comparing actual data with plan data. These variances calulates enable you to control business flows.

Integration:

Integration of FI-CO

Now as all the major flow or costs and revenues flow in CO through FI through direct or indirect allocation, it is an evident integration between the two modules considering the output we fetch from the same. CO has more of internal usage of the cost incurred to help the organization make decisions and maintain control and have an overview of the details cost and revenue structure. Now once the cost flows from FI and in CO, CO within the module also has its own allocation and reallocations to put the costs and revenue ultimately where the same belongs. It mostly depends on your organization structure and what areas are to be monitored and are cost and revenue collecting units to see the profitability of the business. You also need to keep in mind the stakeholders and other decision makers to evaluate this scenario. So as we have closing cycles for financial books the same exists in CO as CO closing cycles. CO also helps in calculating actual versus planned Values to keep a check in an organization.

There are various ways through which CO costs and revenues are booked in SAP. To give a minimum overview of the ways values flow from the sender to receiver is based on various processes in each module, which are mentioned below. Each module will have many such processes internally. Like below are some processes, which can be highlighted to understand the same.

Plant And Maintenance: The Plants and Machinery have cost objects defined in their Master data. Where in when the Machineries are used in the production activity the fixed and the variable costs get booked. The efficiency and the utility of the machinery also need to be taken in account.

Sales distribution: The Sales cycle and in the sale order has revenue objects attached to the same to transfer Values from SD to CO.

Material Management: The Material Master data has profit centers attached to the same which helps collecting costs and revenues incurred through the Materials.

Likewise, let's take FI-CO integration processes:

So the major Cost Objects used in SAP FI are:

|

|

Posted: 27 Jul 2016 06:32 AM PDT

Finance being an integral part in the SAP ERP plays a significant role in cross module integration. The processes are intervened and connected to different modules to avoid redundancy of data entry and taking advantage of the ERP system in their daily process. Helping an organization in optimizing resources.

Financials need to be updated only in certain business steps and not throughout the Organizational proceedings. Inter-module integration hence helps in smooth running of the business throughout. Sales and distribution Module has its own set of data entries, tables, master data, programs, transaction code, processes, system etc. Every organization is structured in a different way. Points of integration of Sales and Distribution and Finance:

These master data have three segments considering the integration of usage of master records in different modules. Customer Master Record

Vendor Master Record

Products/ Services.

Products and services are combined in the SAP under the term Material. As information necessary for the management of a material and its stock, as well as its use, is maintained in the so-called material master record.

Let us understand the sales process and its integration of SD and FI.By assigning Sales organizations and plants you are create a link between company codes and sales organizations. Within a company code, can be assigned to different sales organizations. Within a company code several sales organizations can be active. Business transactions can also be carried out between different company codes (for example, during intercompany sales processing.) Sales Process:

How are GL accounts triggered through the Pricing is shown by a simple flow below:

•Company Code Segment

|

No comments:

Post a Comment